Circuitry and Systems

AI's Role in Electronic Manufacturing

Welcome to the heart of electronic manufacturing’s evolution. In a world where precision, efficiency, and sustainability are paramount, AI’s Role in Electronic Manufacturing has emerged as the guiding star. This journey unravels everything from the assembly lines powered by robotic marvels to the eco-friendly practices reshaping the sector.

Join us as we navigate through component quality assurance, streamlined supply chains, innovative designs, and more. Discover how training for AI is equipping professionals for this digital age, and peek into the crystal ball to see what the future holds.

This electrifying voyage invites you to envision how AI is not just a tool but the driving force propelling electronic manufacturing into a remarkable future.

Table of Contents

The evolving landscape of electronic production

In the thrilling realm of electronics, change is the only constant. AI in electronics production has sparked a revolution, rewriting the industry’s playbook. Imagine machinery that never falters—thanks to predictive maintenance for machinery—and supply chains that flow like a well-choreographed dance, all thanks to AI for optimizing electronic supply chains.

Robots, the tireless performers, have taken centre stage in robotics in electronics assembly, ensuring precision like never before. Meanwhile, the design phase has metamorphosed, with AI-driven electronic design conjuring innovative marvels. Sustainability is no longer an afterthought; it’s integral to sustainable electronics production.

But hold on tight; we’re just getting started. Before diving into this evolving landscape’s deep waters, remember that training for AI in electronics is critical. Our journey through this electrifying universe will take us through remarkable case studies of AI in electronics. Then, we’ll cast our gaze forward, exploring tantalizing future trends in electronic manufacturing. So, are you ready to embark on this electrifying journey, curious about the role of AI in electronic manufacturing and how it’s transforming the industry?

Now, let’s delve into the heart of the matter: Ensuring component quality with ML.

Ensuring component quality with ML

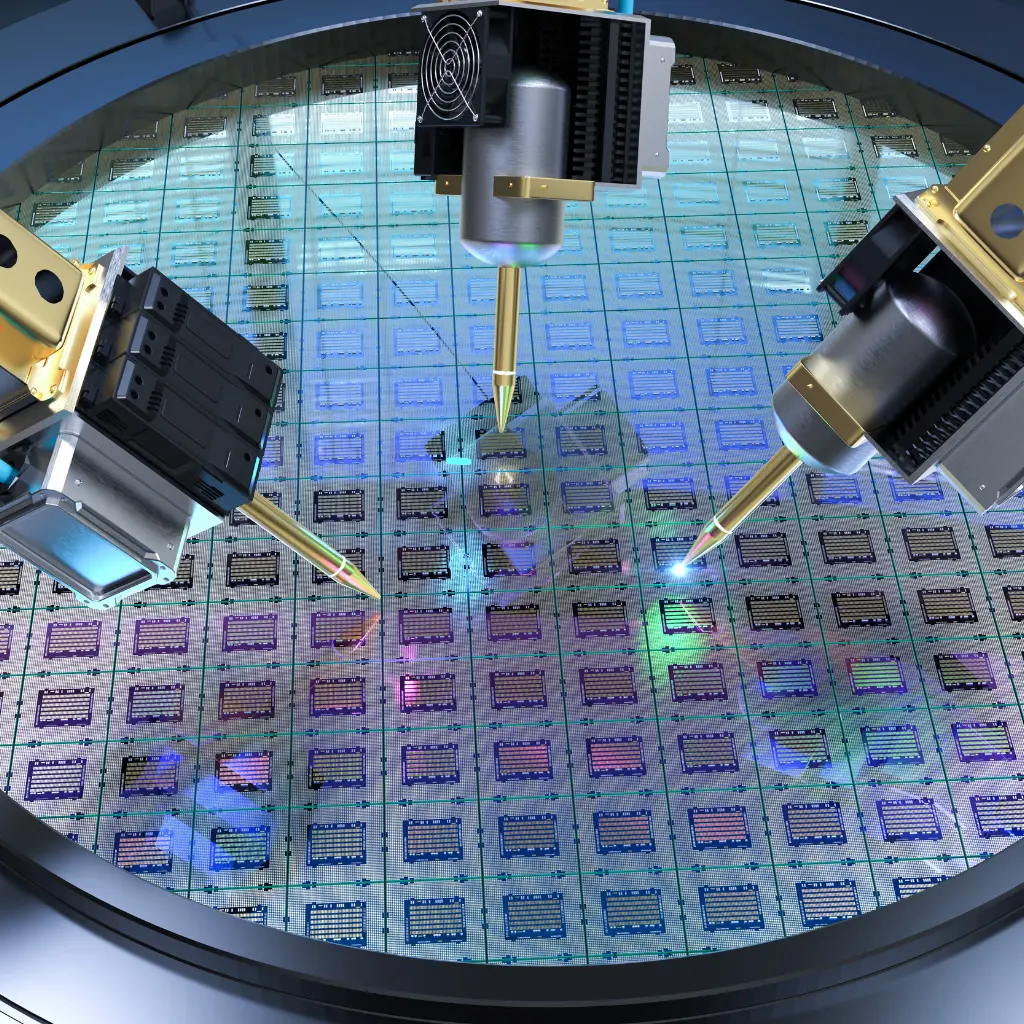

In the fast-paced world of electronic manufacturing, precision is paramount. Building on the evolving landscape of electronic production, AI’s role in electronic manufacturing extends to ensuring component quality with ML. As electronics become increasingly intricate, each component’s reliability is crucial.

Imagine a world where every resistor, capacitor, and microchip is scrutinized with unmatched precision, thanks to machine learning in component checks. Imperfections and anomalies are identified with lightning speed, ensuring that only the highest-quality components are cut.

But here’s the real kicker: this is just one piece of the puzzle. What happens when these meticulously crafted components come together in the machinery? How do we ensure they continue to function flawlessly over time? Our journey takes us next to the realm of machinery maintenance made efficient.

Picture a factory floor where machinery communicates its needs and predicts its maintenance requirements. How can AI play a pivotal role in making this happen? What benefits does this hold for the electronic manufacturing industry? Join us as we explore the fascinating world of predictive maintenance.

Machinery maintenance made efficient

Now that we’ve ensured component quality through machine learning in component checks let’s dive into the heart of operational excellence in electronic manufacturing: machinery maintenance made efficient.

In our high-tech landscape, machinery is the backbone of production. But what if it could predict its maintenance needs, aligning perfectly with AI’s role in electronic manufacturing? This isn’t science fiction; it’s the future.

Imagine a world where machines alert you before a breakdown, thanks to predictive maintenance for machinery. Minimizing costly downtimes ensures that production flows seamlessly. AI monitors the health of every machine, learning patterns and predicting when care is needed.

But here’s the intriguing part: How does this impact the broader picture of electronic manufacturing, especially the complex web of supply chains? How can efficient machinery maintenance contribute to streamlined supply chains, ensuring products reach their destination faster? Let’s embark on this journey together, exploring the interconnected world of AI and supply chain optimization in electronic manufacturing.

Streamlined supply chains

Having explored how efficient machinery maintenance dovetails with AI’s role in electronic manufacturing, let’s unravel another vital strand of this transformative tapestry: streamlined supply chains.

In electronics, time is money, and every moment counts. How can AI optimize the process from raw materials to finished products? Imagine a supply chain that responds in real time to market demands, just like predictive maintenance for machinery. Products move seamlessly from production lines to customers’ hands.

But here’s the intrigue: What is the secret sauce behind this efficiency, and how can AI synchronize the myriad components of the supply chain to ensure timely deliveries and minimal waste? Our voyage takes us next into the realm of AI for optimizing electronic supply chains.

Picture a world where AI is the conductor orchestrating the supply chain symphony. How does this impact the electronics industry’s competitiveness and sustainability? What benefits await as we explore this symphony of supply chain innovation? Join us on this exciting journey into the future of electronic manufacturing.

Now, let’s turn our attention to the precision performers of the industry: robots in precision electronics assembly. How do these robotic wonders contribute to the flawless assembly of intricate electronic devices?

Robots in precision electronics assembly

From streamlined supply chains, we venture into the world of robots in precision electronics assembly, where efficiency and accuracy merge seamlessly with AI’s role in electronic manufacturing.

Picture an assembly line where robots guided by artificial intelligence dexterously place microchips and solder components with pinpoint accuracy. These robots work tirelessly to flawlessly assemble electronic devices and ensure the precision of machine learning in component checks.

But how do these robots learn and adapt to ever-evolving electronic designs? How does AI empower them to handle intricate tasks with finesse, making them an invaluable asset to electronic manufacturing? Our journey now takes a captivating twist, diving deep into the realm of innovative designs powered by AI.

AI-driven design processes create new, unimaginable electronic wonders. How does this impact the industry’s ability to innovate and meet the growing demands for cutting-edge electronics? Join us as we explore the artistry of electronic design powered by artificial intelligence.

Now, let’s delve into sustainability in electronic manufacturing, focusing on green manufacturing in the electronics sector. How is AI contributing to a more eco-friendly future?

Innovative designs powered by AI

From the precision dance of robots in assembly, our journey leads us to the captivating world of AI-powered innovative designs. Here, the creative sparks of electronic manufacturing are fanned into a blazing revolution, building upon the efficiencies of AI’s role in electronic manufacturing.

Imagine designers wielding AI as their artistic muse, crafting electronic marvels that push boundaries. These intelligent design processes don’t just follow trends; they set them, all while aligning seamlessly with the precision achieved in machine learning in component checks.

But how does AI transform the design process? How does it enable designers to innovate faster, dream bigger, and create once-impossible wonders? Our exploration now turns toward the green horizon of green manufacturing in the electronics sector.

Picture a world where innovation meets sustainability, where AI-driven design processes create groundbreaking electronics and reduce environmental impact. How does this transformation benefit our planet and the industry as a whole? Join us on this voyage into the eco-conscious future of electronic manufacturing.

Now, let’s dive deeper into sustainable practices focusing on green manufacturing in the electronics sector. How are electronic manufacturers embracing eco-friendly processes, and what are the tangible benefits of these efforts?

Green manufacturing in the electronics sector

From the realm of innovative designs, where AI breathes life into electronic marvels, our journey takes an eco-conscious turn toward green manufacturing in the electronics sector. How can the creativity unleashed by AI’s role in electronic manufacturing be harnessed for a greener future?

Imagine factories that minimize waste, reduce energy consumption, and embrace sustainable practices perfectly harmoniously with the precision of robots in precision electronics assembly. Sustainability is not just a buzzword; it’s the guiding principle.

But how is AI playing a pivotal role in this green transformation? How are electronic manufacturers reimagining their processes to align with environmental goals? Our exploration now turns to the future-ready topic of preparing for the digital shift.

Picture a landscape where digitalization and sustainability converge. How does this synergy empower electronic manufacturers to thrive in a rapidly evolving world? Join us as we explore the strategies and technologies driving electronic manufacturing into the digital age.

Now, let’s prepare ourselves for the digital revolution with a focus on training for AI in electronics. How are industry professionals gearing up for this transformative shift, and what skills will be essential in the AI-powered future of electronic manufacturing?

Preparing for the digital shift

As we explore the strides made in green manufacturing in the electronics sector, it becomes clear that the future of electronic manufacturing hinges on preparedness for the impending digital shift. How will the industry adapt to the evolving landscape shaped by AI’s role in electronic manufacturing?

Picture this: Professionals upskilling and reskilling to harness the potential of AI, much like machines that optimize production. Training is no longer a luxury; it’s necessary in a world where training for AI in electronics is the gateway to staying relevant.

But what does this training entail, and how does it empower individuals to drive the industry forward? Our journey now turns its spotlight on the remarkable spotlight on industry successes. What lessons can we learn from organizations and professionals who have already embraced these changes?

Imagine a world where electronic manufacturers are not just adapting but thriving, powered by AI-driven innovations and sustainability efforts. What success stories lie on the horizon, and how can we all be part of this exciting transformation? Join us as we unveil these industry triumphs and gather insights for the journey ahead.

Spotlight on industry successes

As we journey through the transformation brought about by AI’s role in electronic manufacturing, our spotlight now turns to industry successes. How have forward-thinking organizations and professionals already harnessed the power of AI to propel the sector into the future, building upon their preparations for the digital shift?

Imagine companies achieving unprecedented efficiency thanks to AI-driven precision assembly and sustainable practices. These success stories demonstrate the tangible impact of embracing change, just as individuals invest in training for AI in electronics to stay at the forefront of innovation.

But what can we learn from these pioneers? How have they navigated the evolving landscape of electronic production, ensuring component quality, efficient machinery maintenance, and streamlined supply chains? Our exploration now sets its sights on the crystal ball as we unveil predictions for the sector’s future.

Picture a world where AI continues to push the boundaries of what’s possible in electronic manufacturing. What exciting developments await, and how can we anticipate and shape the future of this dynamic industry? Join us as we gaze into the electronic horizon and speculate on the incredible possibilities that lie ahead.

Predictions for the sector's future

As we shine a light on the inspiring achievements in electronic manufacturing, it’s only natural to wonder about the path ahead. How will the successes we’ve explored, driven by AI’s role in electronic manufacturing, shape the sector’s future?

Envision a landscape where AI streamlines production and enhances product personalization. As companies delve into AI-driven electronic design, we can anticipate consumer electronics that cater to individual needs with unprecedented precision.

Yet, the transformation goes beyond the assembly line. Sustainability, ingrained in green manufacturing in the electronics sector, will become non-negotiable. Predictions suggest electronic manufacturing will be synonymous with environmental stewardship, reducing waste and energy consumption.

So, what does this all mean for professionals in the field, considering the importance of training for AI in electronics? How can they prepare for this exciting future where AI-driven innovations are the norm and sustainability is paramount?

As we conclude this exploration of AI’s role in electronic manufacturing, we invite you to ponder: What role will you play in shaping the electronic manufacturing landscape of tomorrow, and how will you contribute to the sector’s evolution?

Conclusion

One thing is evident in the electrifying world of electronic manufacturing: AI’s Role in Electronic Manufacturing is not just a trend; it’s the driving force behind an industry metamorphosis.

We’ve journeyed through this transformation, starting with the evolving landscape of electronic production, where AI orchestrates precision and efficiency. Machine learning in component checks ensures that each piece meets the highest standards.

Efficient machinery maintenance and streamlined supply chains have become the industry norm, with AI’s predictive prowess at the helm. Robots, guided by artificial intelligence, meticulously handle intricate tasks in electronics assembly.

AI-driven electronic design has unlocked the door to innovation, creating marvels previously deemed impossible. Sustainability, a vital part of this revolution, has birthed green manufacturing in the electronics sector.

Professionals are training in AI for electronics to prepare for the digital age. Industry successes exemplify the potential when AI and innovation converge.

Now, what lies ahead? Predictions point to even greater personalization, sustainability, and integration of AI in electronic manufacturing. The future is in the hands of those who dare to embrace this transformative wave.

So, as we conclude our journey, ask yourself: How will you shape the future of electronic manufacturing, harnessing the power of AI to create a more efficient, sustainable, and innovative industry? It’s a world where the electronic marvels of tomorrow are limited only by our imagination and willingness to adapt.

Related Articles

- AI in Paper Manufacturing: Pulp and Processors

- AI in Agri-Equipment Manufacturing: Fields and Functions

- AI in Footwear Manufacturing: Steps Ahead

- AI in Jewellery Manufacturing: Gems and Generative Models

- AI in Glass Manufacturing: Crystal Clear Computing

- AI in Construction Material Manufacturing: Bricks and Bytes

- AI in Chemical Manufacturing: Molecular Models

- AI’s Revolution in Polymer Production: Reshaping Plastics

- AI in Furniture Manufacturing: Crafted by Code

- AI in Ceramic Production: Fired by Future

- AI in Food Manufacturing: Savory Systems

- AI in Metal Fabrication: Moulded by Machines

- AI in Aerospace Manufacturing: Beyond the Atmosphere

- AI’s Integration in Pharmaceutical Manufacturing: Pills and Processes

- AI in the Automotive Industry: Driving Production

- Weaving AI into Textile Manufacturing: Threads and Tech

- IPA in Manufacturing Sector: How AI Tools Revolutionize Efficiency, Productivity, and Quality

Arindam Roy

An Automation Consultant with 25+ years of IT Experience

Forbes Articles related to AI usage in the Manufacturing Sector: