Beyond the Atmosphere

AI in Aerospace Manufacturing

Welcome to the cutting-edge world of aerospace manufacturing, where innovation meets sustainability and AI takes centre stage.

Explore a world of limitless aircraft design and optimized supply chains. Witness robotics redefine precision assembly, and sustainability becomes a driving force.

Come and join us on an exciting journey to explore the world of AI in aerospace manufacturing. Join us as we uncover the achievements of industry pioneers and peer into the future, where the skies are no longer the limit but a horizon filled with endless possibilities.

Table of Contents

Innovations in Aerospace Manufacturing

From the assembly line to the digital frontier, AI in aerospace production has ushered in a new era of efficiency and precision. These cutting-edge technologies transform how aircraft are conceived, crafted, and catapulted into the skies.

ML for quality checks in parts stands as a testament to this revolution. Machine Learning algorithms meticulously scrutinize every nut, bolt, and panel, ensuring that each component meets the highest standards of excellence. The result? Impeccable aircraft parts, ready to defy gravity.

But it doesn’t stop there. Predictive maintenance in aerospace takes centre stage, forecasting when machines need a little TLC before they even hint at wear and tear. This foresight extends the lifespan of vital machinery, curbing costs and preventing unexpected downtime.

The supply chain, a lifeline in aerospace, undergoes a profound evolution. AI streamlines the aerospace supply chain for just-in-time parts delivery.

Now, let’s talk assembly. Robots, meticulously programmed and fine-tuned, waltz onto the scene. Their nimble fingers gracefully handle even the tiniest components, showcasing the pivotal Role of Robotics in aircraft assembly.

AI algorithms provide insights to design aircraft with data. Through this process of symbiosis, AI-driven aerospace design brings forth creations that not only soar through the sky but do so with unprecedented efficiency and grace.

As we forge ahead, a vital question arises: How do we ensure that every component is exceptional? Join us in our next adventure as we delve into Ensuring top-notch component quality. How does AI continue to set new standards for perfection?

Ensuring Top-Notch Component Quality

Building on the foundations of AI-driven innovations, the quest for excellence in aerospace manufacturing continues with a laser focus on component quality. How does AI in Aerospace Manufacturing guarantee that every piece of the puzzle meets the highest standards?

Machine learning algorithms take centre stage for quality checking in parts precision. They scrutinize every nook and cranny of aircraft components with unwavering attention to detail. This meticulous examination ensures that each piece emerges as a masterpiece of engineering, meeting and often exceeding industry benchmarks.

But the journey doesn’t end here. Predictive analytics, a beacon of hope for machinery longevity, casts its influence. By providing predictive insights for machinery longevity, AI offers a window into the future, predicting when components might need attention. This foresight extends the life of critical parts and prevents unexpected failures, enhancing safety and reliability.

Consider the rivets that hold an aircraft together. With the aid of AI, their composition and integrity are scrutinized with surgical precision. Supply chain optimization for aerospace ensures that only the finest materials find their way into the manufacturing process. The result? Every rivet, a testament to excellence, contributes to the overall strength and durability of the aircraft.

As we marvel at the seamless integration of AI into the quest for perfection, we can’t help but wonder: What other insights can AI offer to ensure the longevity of our machinery? Join us in our next journey, where we dive into the world of Predictive insights for machinery longevity. How does AI continue to safeguard the heartbeats of aerospace manufacturing?

Predictive Insights for Machinery Longevity

As we delve into Ensuring top-notch component quality, it’s important to note that AI in Aerospace Manufacturing has yet another intriguing facet – the ability to predict the future of machinery. This game-changer can save time, reduce costs, and improve efficiency. By utilizing AI, we can expect issues and prevent them. This ensures the smooth functioning of machinery and helps us stay ahead of the competition. But how does AI perform this seemingly magical feat?

AI can predict when maintenance is needed for a jet engine by analyzing data. This level of insight, rooted in ML for quality checks in parts, ensures that these engines can keep flying safely and efficiently for years.

But it’s not just engines; AI extends its predictive capabilities to every facet of aerospace machinery. Advanced algorithms, often powered by predictive maintenance in aerospace, can anticipate when a gearbox might require attention or when a hydraulic system may need servicing.

This predictive capability saves time, money, and lives by making aircraft safer and more reliable with AI-powered predictive systems. Pilots can trust that their machines are in peak condition, making air travel even more secure.

As we marvel at AI’s ability to predict the future of aerospace machinery, we must ask: How does this predictive power contribute to the broader goal of Streamlined aerospace supply chains? How can anticipation reshape the aerospace industry? Join us in our next exploration.

Streamlined Aerospace Supply Chains

Building upon the foundation of predictive insights, AI redefines the aerospace manufacturing landscape, leading us to explore the crucial domain of streamlined aerospace supply chains. But how does AI in Aerospace Manufacturing contribute to a seamless flow of parts and materials?

Imagine an intricate dance where every component arrives at the right place and time without missing a beat. AI orchestrates this symphony, ensuring that the principles of predictive maintenance in aerospace extend beyond the machinery. By anticipating the need for parts, AI minimizes downtime, keeping production lines humming.

Supply chains are notorious for their complexity, but AI unravels the tangle. Through the precision of ML for quality checks in parts, AI optimizes inventory management. No more excess stockpiles or frantic last-minute orders; every item finds its purpose without waste.

But the magic doesn’t stop there. With supply chain optimization for aerospace, AI considers variables like weather conditions and geopolitical factors, planning routes and logistics with unimaginable sophistication. Components move with clockwork precision.

As we witness the aerospace supply chain transformed by AI, we ponder the next chapter: How do robots, guided by AI, contribute to the meticulous Role of robotics in precision assembly? How can automation redefine aerospace manufacturing even further? Join us in our next journey through the world of robotics and aerospace.

Role of Robotics in Precision Assembly

With our journey through streamlined supply chains, we’ve glimpsed the orchestration of components, all thanks to AI. But how does AI make sure every piece fits together flawlessly? Enter the fascinating world of the Role of robotics in precision assembly.

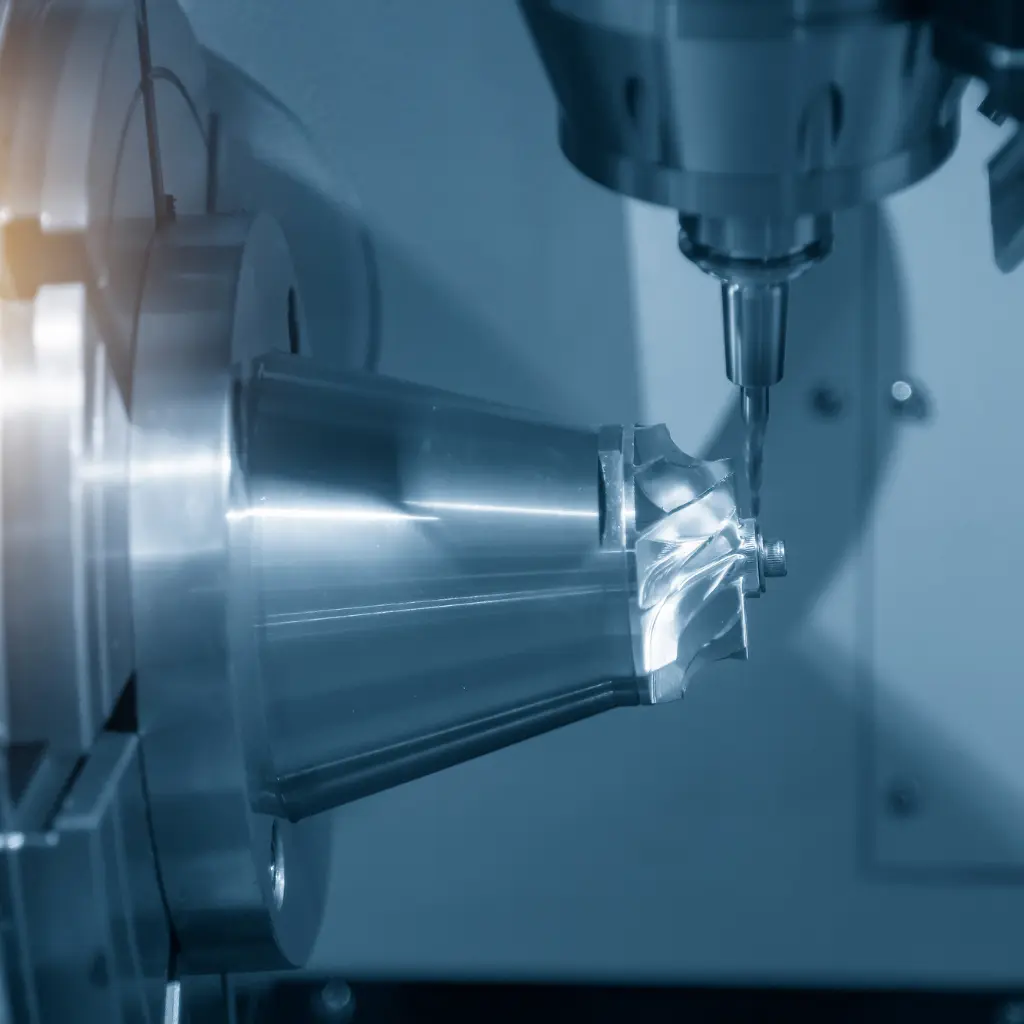

Think of robots as the master craftsmen of the aerospace industry. Guided by AI algorithms, they handle the most delicate tasks with unparalleled precision. Robots excel When attaching intricate components or welding aircraft frames, guaranteeing not a fraction of an error.

Robots don’t tire or lose focus. They tirelessly repeat their tasks with the consistency that humans can only dream of. This relentless work ethic, supported by predictive maintenance in aerospace, ensures that each aircraft that rolls off the assembly line is a masterpiece of engineering.

But it’s not just about accuracy; it’s also about speed. With ML for quality checks in parts, robots swiftly inspect and verify components, making the assembly process more efficient than ever before. No more waiting for human inspectors; AI-backed robots keep the production line flowing smoothly.

As we marvel at the precision and efficiency of robots in aerospace assembly, we naturally wonder: How can AI take its Role even further in Designing aircraft with AI insights? What future innovations will redefine the very concept of aircraft design? Join us on our next voyage into the realm of AI and aerospace.

Designing Aircraft with AI Insights

As we’ve witnessed the remarkable precision of robotics in aerospace assembly, the natural question is: How can AI contribute to the genesis of aircraft? The answer lies in the captivating world of Designing aircraft with AI insights.

Traditionally, aircraft design was a realm of immense human expertise, but AI rapidly became the co-pilot. AI algorithms collaborate with engineers to optimize aircraft shape, structure, and materials using data from flights and simulations. This synergy, driven by AI in Aerospace Manufacturing, results in aircraft that are not just aerodynamic marvels but also incredibly fuel-efficient.

But AI’s Role goes beyond mere efficiency. It delves into sustainability, a key focus in modern aerospace. By analyzing data on emissions, fuel consumption, and materials, AI contributes to the realization of sustainable aerospace practices. It helps design aircraft with a smaller carbon footprint, making aviation more environmentally friendly.

Moreover, AI doesn’t just optimize for the present; it anticipates the future. Through its predictive capabilities, AI provides insights into how aircraft designs can evolve to meet the changing needs of passengers and the industry. This proactive approach, rooted in predictive maintenance in aerospace, ensures that the aerospace industry remains on the cutting edge of technology.

When considering the impact of AI on the aerospace industry, we must examine how it can promote sustainability in aircraft design. How can we ensure that the skies remain blue for generations to come? Join us as we embark on our next adventure in pursuing a greener, more innovative aerospace industry.

Promoting Sustainability in Aerospace

Having glimpsed the remarkable strides of AI in aircraft design, we now find ourselves at the crossroads of innovation and environmental responsibility. How does AI in Aerospace Manufacturing advance the cause of Promoting sustainability in aerospace?

One of AI’s pivotal roles is in reducing carbon emissions. By optimizing aircraft design, AI contributes to fuel-efficient planes that consume less and emit fewer greenhouse gases. The marriage of AI insights with sustainable aerospace practices ensures that we fly cleaner, with a reduced impact on our planet.

Moreover, AI doesn’t merely stop at design; it extends its hand to streamline operations. By coordinating flights, optimizing routes, and reducing idle time, AI bolsters the quest for sustainability. It’s the driving force behind airlines and manufacturers adopting supply chain optimization for aerospace with a green twist.

But the true marvel lies in AI’s predictive abilities. By forecasting maintenance needs and minimizing downtime, AI reduces the need for aircraft replacements, which are costly and resource-intensive. This strategy, rooted in predictive maintenance in aerospace, saves money and preserves valuable resources.

As we navigate the path toward a more sustainable aerospace industry, we must ponder: How are industry leaders Adapting to the AI-driven industry shift? What changes await us in the wake of this technological revolution? Join us as we venture into the world of AI-driven adaptation in aerospace.

Adapting to the AI-Driven Industry Shift

With sustainability at the forefront, we’ve witnessed AI’s transformative power in aerospace. But how do industry leaders navigate this shifting landscape shaped by AI in Aerospace Manufacturing?

The adaptability of AI is a hallmark of its significance. It’s not just about designing aircraft or optimizing supply chains; it’s about embracing a new way of doing things. Aerospace giants actively invest in AI research and development, seeking ways to align their operations with streamlined aerospace supply chains and eco-friendly practices.

Human expertise remains invaluable. AI is not here to replace but to enhance. Aerospace professionals are learning to collaborate seamlessly with AI systems. They’re becoming proficient in interpreting the insights offered by ML for quality checks in parts and using them to make informed decisions.

Furthermore, the AI-driven industry shift brings with it a demand for a different skill set. Aerospace companies are committed to training the workforce for AI – equipping their teams with the knowledge and tools to thrive in this evolving landscape.

But the most intriguing aspect is the potential for future breakthroughs and achievements. Industry pioneers who have embraced the full spectrum of AI in Aerospace Manufacturing are poised to revolutionize the industry. What remarkable feats await these innovators? How will their contributions shape the future of aerospace? Join us as we celebrate their achievements in our next exploration.

Highlighting Industry Pioneers and Their Achievements

As we traverse the dynamic landscape of aerospace transformed by AI, it’s only fitting to spotlight the pioneers who have boldly embraced the AI-driven industry shift. These trailblazers, navigating the realms of AI in Aerospace Manufacturing, are redefining the fabric of the aerospace industry.

Their achievements are awe-inspiring. Aerospace manufacturers have pushed the boundaries of design, crafting aircraft that are not just engineering marvels but also sustainability champions. Their creations, driven by AI insights, set new standards in sustainable aerospace practices, marking a paradigm shift in how we view air travel.

Supply chains, once labyrinthine, have been streamlined by these visionaries. They’ve harnessed the potential of supply chain optimization for aerospace, ensuring that components flow seamlessly from supplier to assembly line, enhancing efficiency, and reducing environmental impact.

In precision assembly, pioneers have harnessed the power of AI-driven robotics, creating assembly lines that hum with speed and precision. These advances, underpinned by the Role of robotics in precision assembly, have not only elevated the quality of aerospace components but have also opened the door to new possibilities in automation.

But what lies on the horizon for these pioneers? How will they continue to shape the aerospace industry? As we look towards the future, we must ask ourselves: what lies ahead for aerospace manufacturing? What untapped potentials await us in this ever-evolving landscape? Join us as we explore the frontiers of aerospace manufacturing, guided by the visionaries who lead the way.

The Future Horizon of Aerospace Manufacturing

As we celebrate the accomplishments of industry pioneers who have harnessed the potential of AI in Aerospace Manufacturing, our gaze inevitably turns toward the limitless possibilities that lie ahead. What awaits us on the future horizon of aerospace manufacturing?

Innovation knows no bounds. Aircraft design, already a symphony of art and science, will continue to evolve with AI’s guiding hand. The question is more than how efficiently we can make planes; what new frontiers can we conquer with designs that push the boundaries of possibility?

Now finely tuned, supply chains will become even more responsive and agile. The fusion of AI and streamlined aerospace supply chains will usher in an era where components arrive just in time, fueling a dynamic aerospace ecosystem.

Robotics, the tireless artisans of assembly lines, will grow in sophistication. We’ll witness the next level of precision and autonomy, making the Role of robotics in precision assembly a cornerstone of aerospace manufacturing.

As sustainability becomes imperative, pioneering efforts in sustainable aerospace practices reshape the industry. The skies will be filled with aircraft with a gentler environmental footprint, thanks to AI-driven innovations.

But the most exciting question is this: Who will lead the charge into this brave new world of aerospace manufacturing? As we embark on this journey, we must wonder: What Role will you play in shaping the future horizon of aerospace manufacturing?

Conclusion: Charting the Future Skyline with AI in Aerospace Manufacturing

In our voyage through the aerospace industry, we’ve witnessed the transformative power of AI in Aerospace Manufacturing. From innovations in design to streamlined supply chains and the rise of robotics in precision assembly, AI has left an indelible mark.

Industry pioneers, driven by a commitment to sustainability and propelled by predictive maintenance in aerospace, have set the course for a greener and more efficient future. They’ve demonstrated how AI can optimize operations and safeguard our planet.

But what lies ahead on the horizon of aerospace manufacturing? The future promises even more extraordinary breakthroughs. Designs will reach new heights, making air travel efficient and awe-inspiring. Supply chains will become even more nimble, bolstered by AI’s predictive insights. Robotics will advance to redefine assembly processes with precise and autonomous operations guided by sustainable practices for a brighter future.

In this ever-evolving landscape, one question remains: How will you contribute to the future horizon of aerospace manufacturing? Will you be a pioneer, shaping the industry’s future, or a beneficiary, reaping the rewards of these remarkable advancements?

As we conclude our journey through the world of AI in aerospace, let’s remember that the sky is no longer the limit. With AI as our co-pilot, we’re charting a course to new horizons where innovation and sustainability go hand in hand, and the future of aerospace manufacturing is brighter than ever.

Related Articles

- AI in Paper Manufacturing: Pulp and Processors

- AI in Agri-Equipment Manufacturing: Fields and Functions

- AI in Footwear Manufacturing: Steps Ahead

- AI in Jewellery Manufacturing: Gems and Generative Models

- AI in Glass Manufacturing: Crystal Clear Computing

- AI in Construction Material Manufacturing: Bricks and Bytes

- AI in Chemical Manufacturing: Molecular Models

- AI’s Role in Electronic Manufacturing: Circuitry and Systems

- AI’s Revolution in Polymer Production: Reshaping Plastics

- AI in Furniture Manufacturing: Crafted by Code

- AI in Ceramic Production: Fired by Future

- AI in Food Manufacturing: Savory Systems

- AI in Metal Fabrication: Moulded by Machines

- AI’s Integration in Pharmaceutical Manufacturing: Pills and Processes

- AI in the Automotive Industry: Driving Production

- Weaving AI into Textile Manufacturing: Threads and Tech

- IPA in Manufacturing Sector: How AI Tools Revolutionize Efficiency, Productivity, and Quality

Arindam Roy

An Automation Consultant with 25+ years of IT Experience

Forbes Articles related to AI usage in the Manufacturing Sector: