Moulded by Machines

AI in Metal Fabrication

Welcome to the frontier of “AI in Metal Fabrication.” In this era of unprecedented technological advancement, metal shaping is no longer limited to human hands alone. It’s a realm where algorithms and automation collaborate with artisans to create the extraordinary.

This article delves into the myriad facets of this transformation, from modern trends in metal shaping to sustainable practices, celebrating the industry’s trailblazers and envisioning a future where precision, creativity, and sustainability redefine the art of Metal Fabrication.

Join us on a journey through innovation, ingenuity, and limitless possibilities in the world of metalwork.

Table of Contents

Modern Trends in Metal Shaping

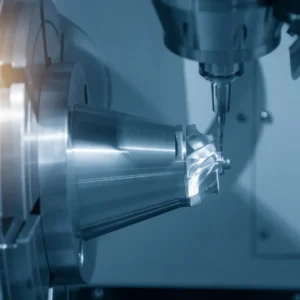

In the dynamic landscape of metal fabrication, the integration of AI in metal shaping stands out as a revolutionary force. Gone are the days of manual hammering and labour-intensive processes.

Now, machines guided by artificial intelligence algorithms sculpt metals with precision and finesse. This marriage of technology and craftsmanship is reshaping the industry.

ML for metallurgy has unlocked new levels of understanding of the behaviour of metals under various conditions. Algorithms analyze vast datasets to predict how metals respond to heat, pressure, and other factors.

This ensures more robust, durable products and paves the way for alloy compositions and performance innovations.

Moreover, predictive analytics for smelting have become invaluable. AI algorithms forecast the optimal conditions for smelting, minimizing waste and maximizing yield.

This reduces environmental impact and boosts profitability, illustrating the potential of green practices in metal fabrication.

As we delve into metal shaping guided by artificial intelligence, the next frontier emerges AI-optimized metal supply chains. How can this transformative technology streamline the flow of raw materials to the heart of the fabrication process?

Come along with us as we delve into how artificial intelligence is transforming the logistics of the metal supply industry. I’ll correct any spelling, grammar, and punctuation errors.

Metallurgy Improvements with AI

AI in Metal Fabrication is leading a new chapter in metal shaping. We’ve witnessed how AI-driven precision shapes metals, but what’s beneath the surface, altering the very essence of metals themselves?

Enter ML for metallurgy, an innovation that penetrates the very atoms of materials. Artificial intelligence doesn’t just shape metal; it refines it. Algorithms dive deep into the molecular structure, predicting how metals behave under stress, temperature variations, and corrosive environments, ushering in a new era of strength and resilience.

But the evolution doesn’t stop there. With predictive analytics for smelting, AI orchestrates the art of transformation from ore to alloy. This means optimizing the process for efficiency and creating alloys with unattainable properties. The result? Materials that are lighter, stronger, and more durable—revolutionizing industries from aerospace to automotive.

Now, let’s delve even deeper into the crucible of innovation as we explore the efficiency of smelting processes. How does AI fine-tune the heart of metal production, forging a path toward a more sustainable and resource-efficient future?

Efficiency in Smelting Processes

Building on our exploration of metallurgy improvements with AI, we now venture into the fiery heart of metal production. How does AI enhance the efficiency in smelting processes, reshaping the very foundations of metal fabrication?

In the crucible of AI in Metal Fabrication, smelting becomes a finely tuned symphony of heat and chemistry. AI algorithms orchestrate the process precisely, optimizing temperatures and chemical compositions to maximize yield while minimizing waste. The result? Reduced energy consumption and a greener, more sustainable approach to smelting align with the quest for green practices in metal fabrication.

But AI’s impact extends beyond efficiency. It empowers metallurgists with predictive insights, ensuring consistent quality. Through predictive analytics for smelting, anomalies and deviations are detected before they become issues, guaranteeing that each batch of metal meets exacting standards.

As we explore the transformative influence of AI on smelting efficiency, a question arises: How does AI not only optimize smelting but also revolutionize the logistics in metal supply? Join us in the next section as we journey into the world of AI-optimized metal supply chains. How can AI streamline the flow of raw materials, further redefining the landscape of metal fabrication?

AI-Optimized Logistics in Metal Supply

Having witnessed the transformative power of AI in improving metallurgy and smelting efficiency, let’s now journey further down the metal fabrication road. How does AI revolutionize the transportation and management of raw materials, reshaping the foundations of metal supply?

In the realm of AI in Metal Fabrication, logistics take centre stage. AI-optimized metal supply chains are the backbone of a streamlined, efficient process. Intelligent algorithms ensure timely delivery of materials, reducing downtime.

This optimization extends to route planning, where AI selects the most efficient paths, minimizing fuel consumption and carbon emissions—a significant step toward achieving sustainable metal processing. Moreover, predictive analytics help manage inventory levels, reducing waste and costs while maintaining a just-in-time approach.

As we delve into AI’s role in transforming metal supply chains, a vital question arises: How does AI-driven automation further revolutionize metal fabrication? Join us in the next section as we explore the intricate dance between technology and craftsmanship in automation in metal crafting. How does AI shape metal to new heights, ensuring precision and speed?

Automation in Metal Crafting

Building upon the foundation of AI-optimized logistics in metal supply, we now journey into the heart of metal crafting. How does AI usher in a new era of precision and speed, transforming the very nature of AI in Metal Fabrication?

Automation is the guiding star. Robotics in metalwork is where human ingenuity melds seamlessly with AI-driven machinery. Robots, programmed with precision algorithms, sculpt metals with accuracy and speed. The result? Complex, intricate designs brought to life in a fraction of the time it would take human hands.

But it’s not just about physical craftsmanship. AI extends its reach into AI in alloy research, deciphering the molecular codes of metals to create new alloys that were once unimaginable. These alloys exhibit properties like never before—lighter, stronger, and more resistant to wear and tear.

As we explore the intricate dance between technology and craftsmanship, the next horizon beckons: Advanced Alloy Creation using AI. How do these new alloys open doors to uncharted possibilities in metal fabrication? Join us in the next section to witness the birth of alloys that defy convention and shape the industry’s future.

Advanced Alloy Creation using AI

Emerging from the realm of automation in metal crafting, we find ourselves at the threshold of a metallurgical revolution. How does AI in Metal Fabrication shape and redefine the essence of the metals we work with?

The answer lies in the art of alloy creation, now elevated to unprecedented heights by artificial intelligence. Powered by AI in alloy research, scientists and engineers unlock the secrets of material science like never before. Algorithms scrutinize vast databases, identifying the perfect blend of elements to birth alloys with astounding properties.

These alloys are not merely stronger or more resilient but can be customized to fulfil particular industrial demands. Whether it’s aircraft components that need to be lighter yet robust or medical implants requiring biocompatibility, AI-optimized alloys pave the way for groundbreaking innovations.

As we contemplate the limitless possibilities of these newfound materials, the next question arises: How does AI contribute to sustainable metal processing? Join us in the next section as we delve into the eco-conscious side of AI in Metal Fabrication and discover how it’s forging a greener path for the industry. How does AI help ensure that the future of metal fabrication aligns with sustainable practices?

Sustainable Metal Processing

From the realm of advanced alloy creation, the path leads us to a greener, more conscientious future in AI in Metal Fabrication. How does the innovation of alloys align with sustainability, shaping a more eco-conscious industry?

The journey begins with materials engineered for efficiency and longevity, thanks to AI-optimized logistics in metal supply. By reducing waste and energy consumption in production and transportation, we’re already on the path to a more sustainable approach.

Sustainable metal processing isn’t just about the end product but the entire life cycle. During the fabrication process, AI optimizes metal usage to minimize waste. As a result, industries reduce their environmental footprint, taking significant steps toward adopting green practices in metal fabrication.

Furthermore, sustainable practices are also about recycling and reusing metals. AI algorithms can track and identify opportunities for recycling, reducing the need for virgin materials. This brings us closer to a circular economy in metal fabrication.

Yet, as we tread the path of sustainability, another vital aspect beckons our attention: How do we prepare the workforce to integrate AI tools in metal fabrication? Join us in the next section as we explore strategies for training and empowering the human element in this AI-driven future. How can we ensure that humans and machines work hand in hand to shape the metal fabrication landscape sustainably?

Preparing Workers for AI Tools

As we tread the path of sustainable metal processing, it’s crucial to remember that AI in Metal Fabrication is not just about technology; it’s about people. How can we ensure that workers have the skills to use AI tools while maintaining the art of metalwork?

Integrating AI and robotics in metal crafting demands a new skill set. Workers must become proficient in collaborating with intelligent machines, understanding their capabilities, and knowing when human finesse is irreplaceable. How do we bridge the gap between traditional craftsmanship and cutting-edge technology, preparing our workforce for this exciting future?

Training programs and initiatives tailored to the evolving needs of the industry are paramount. Equipping workers with the skills to operate and maintain AI-driven machinery enhances efficiency and empowers them to shape the future of metal fabrication. How can we ensure these training programs are accessible and effective for all?

Moreover, fostering a culture of continuous learning is vital. In a landscape where technology evolves rapidly, adaptability is critical. How do we create an environment where workers are encouraged to embrace AI as a tool that enhances their expertise rather than a threat to job security?

As we explore the dynamic intersection of human talent and AI-driven tools, the next frontier beckons: Who are the industry trailblazers leading the charge in metal fabrication’s AI-powered future? Join us in the next section as we celebrate the pioneers shaping the destiny of this exciting field. Who are the visionaries setting new standards in AI in Metal Fabrication?

Industry Trailblazers in Metal Fabrication

In our exploration of the evolving landscape of AI in Metal Fabrication, we recognize that visionary leaders often drive progress. As we prepare workers for AI tools, it’s imperative to look to those at the forefront of the industry.

These trailblazers are pioneering new techniques that seamlessly merge human expertise with the precision of AI. They embrace automation in metal crafting not as a replacement for skilled artisans but as a means to amplify their capabilities, creating intricate designs and structures that were once impossible.

Moreover, these visionaries spearhead sustainable practices, utilizing AI-optimized logistics to reduce the industry’s environmental impact. They understand the importance of sustainable metal processing in ensuring a greener, more ethical future for metal fabrication.

But it’s not just about technology; it’s about shaping the industry’s culture. Trailblazers foster a learning environment where workers are encouraged to embrace AI as a tool that enhances their craft. They inspire the workforce to adapt and evolve alongside technology.

As we celebrate these industry leaders, a question arises: What is their vision for the future of Metalworks? Join us in the next section as we delve into the aspirations and innovations that will shape the destiny of AI in Metal Fabrication. What dreams and innovations will pave the way for the next chapter?

Vision for the Future of Metalworks

As we celebrate the pioneers shaping the destiny of AI in Metal Fabrication, it’s clear that their vision extends far beyond the present. Industry trailblazers guide us toward a future where metal fabrication is synonymous with innovation and sustainability.

In the future, AI will play an increasingly important role in metal shaping, metallurgy, and logistics optimization. Automation in metal crafting will become even more sophisticated, with machines taking on intricate tasks while skilled artisans focus on design and oversight, marking a shift toward precision and creativity.

The vision includes a global commitment to sustainable metal processing. Industry leaders drive initiatives to reduce waste, energy consumption, and emissions. Ensuring that metal fabrication aligns with eco-friendly practices will equip the workforce with the skills necessary to succeed in an inclusive, AI-driven environment. The collaboration between humans and AI will redefine the art of metalwork, creating a harmonious and prosperous future.

As we gaze ahead, one question lingers: How will you contribute to this vision for the future of Metalworks? Join us in the article’s conclusion as we reflect on the journey we’ve embarked on and the exciting possibilities. What role will you play in shaping the destiny of AI in Metal Fabrication?

Conclusion

In the captivating realm of AI in Metal Fabrication, we’ve journeyed through a landscape marked by innovation, sustainability, and the indomitable human spirit.

From modern trends in metal shaping, where precision reigns supreme, to metallurgy improvements with AI, illuminating the path to alloys that redefine strength, we’ve witnessed an industry transformation. Our exploration extended to the efficiency of smelting processes, AI-optimized logistics, and the remarkable automation in metal crafting.

Venturing more profoundly, we uncovered the secrets of advanced alloy creation using AI, unlocking possibilities beyond imagination. Sustainable metal processing beckoned us toward eco-conscious practices that respect the Earth’s resources.

In preparing workers for AI tools, we embraced a future where technology and craftsmanship harmonize, and industry trailblazers lead the way with visionary innovations.

And now, we stand on the brink of a future where AI’s influence in Metalworks is unknown. A collaborative environment where humans and machines converge to achieve precision, creativity, and sustainability, primed for future challenges and opportunities.

The question remains: What role will you play in this unfolding narrative of AI in Metal Fabrication? As we gaze upon the horizon, filled with visionaries and pioneers, the future awaits your unique contribution. Will you shape the destiny of this remarkable industry, ensuring it remains a beacon of innovation, sustainability, and limitless potential? The future of Metalworks is in your hands.

Related Articles

- AI in Paper Manufacturing: Pulp and Processors

- AI in Agri-Equipment Manufacturing: Fields and Functions

- AI in Footwear Manufacturing: Steps Ahead

- AI in Jewellery Manufacturing: Gems and Generative Models

- AI in Glass Manufacturing: Crystal Clear Computing

- AI in Construction Material Manufacturing: Bricks and Bytes

- AI in Chemical Manufacturing: Molecular Models

- AI’s Role in Electronic Manufacturing: Circuitry and Systems

- AI’s Revolution in Polymer Production: Reshaping Plastics

- AI in Furniture Manufacturing: Crafted by Code

- AI in Ceramic Production: Fired by Future

- AI in Food Manufacturing: Savory Systems

- AI in Aerospace Manufacturing: Beyond the Atmosphere

- AI’s Integration in Pharmaceutical Manufacturing: Pills and Processes

- AI in the Automotive Industry: Driving Production

- Weaving AI into Textile Manufacturing: Threads and Tech

- IPA in Manufacturing Sector: How AI Tools Revolutionize Efficiency, Productivity, and Quality

Arindam Roy

An Automation Consultant with 25+ years of IT Experience

Forbes Articles related to AI usage in the Manufacturing Sector: