Driving Production

AI in the Automotive Industry

The automotive industry, once defined by the roar of engines and the clank of machinery, is undergoing a profound transformation. At the heart of this evolution is AI in the Automotive Industry. This dynamic exploration delves into AI’s pivotal role in revolutionizing how we conceive, manufacture, and drive automobiles.

From the precision of machine learning for quality control to the foresight of predictive maintenance, AI has become the driving force behind enhanced efficiency and reliability in automotive production. It orchestrates supply chains, ensuring every component arrives precisely when needed, optimizing operations, and reducing waste.

Robots and humans collaborate seamlessly on assembly lines, creating vehicles designed for safety, sustainability, and style. Skilled workforces are essential to unlocking the full potential of AI. They are poised to spearhead a new era of creativity and productivity by combining traditional craftsmanship and high-tech innovation. Skilled professionals can shape the world’s future with proper training and resources.

Success stories serve as beacons, illuminating the path forward, while questions about data privacy and adaptability to real-world unpredictability remain on the horizon.

Join us as we embark on a journey through the present and future of the AI-driven Automotive Industry, where every milestone promises innovation, and every innovation promises a brighter, more sustainable, and efficient future.

Table of Contents

AI's Transformative Role in Automotive Production

In the AI-driven automotive industry, innovation is shifting gears like never before. With the relentless pursuit of perfection, machine learning for quality control is revving production lines.

But it doesn’t stop there. Predictive maintenance in auto plants is changing the game, preventing breakdowns before they even think of happening. Think about the possibilities – reduced downtime, improved efficiency, and cost savings that could revitalize the entire industry.

Supply chains are also getting a major overhaul, thanks to AI-driven supply chain optimization. The result? Streamlined operations, quicker deliveries, and happier customers.

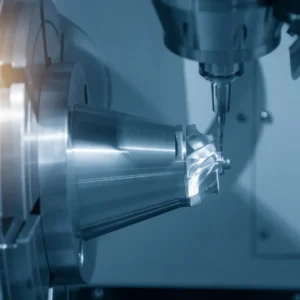

Car assembly robotics revolutionizes the way vehicles are put together on assembly lines. With the help of robotic technology, automakers are transforming the traditional car manufacturing processes. These mechanical marvels tirelessly work alongside humans, boosting productivity and enhancing safety.

And it’s not just about making cars; it’s about designing them too. AI in automotive design pushes boundaries, creating sleeker, safer, and more efficient vehicles.

The most exciting twist is the green revolution. Sustainability through AI is steering the auto industry towards eco-friendly practices. The question is, what’s next for this high-speed journey? How does AI elevate quality checks to the next level? Let’s dive into it.

Enhancing Quality Checks with ML

Building on the foundation of AI’s transformative role in Automotive production, let’s zoom in on a pivotal aspect: quality checks. How can we ensure each vehicle meets the highest standards? The answer lies in Machine Learning for quality control.

Picture a system that learns, adapts, and refines its understanding of perfection. It identifies even the minutest imperfections through mountains of data, ensuring flawless finishes and precise welds. How? By leveraging the power of AI in the Automotive Industry.

This isn’t just about catching defects; it’s about preventing them. Machine Learning algorithms analyze patterns, foreseeing potential issues long before they materialize. Imagine a world where imperfections are a thing of the past, thanks to the foresight of predictive maintenance in auto plants.

But what does this mean for downtime? By utilizing quality checks powered by machine learning, it is possible to minimize disruptions. The production line flows smoothly without hiccups caused by faulty components. Efficiency soars, costs plummet, and customers receive vehicles of impeccable quality.

Yet, there’s another frontier to conquer: predictive maintenance. How can we harness the power of AI to foresee maintenance needs, preemptively avoiding costly breakdowns? The journey continues as we explore reducing downtime with predictive maintenance. How will this innovation reshape the landscape of automotive production? Let’s find out.

Reducing Downtime with Predictive Maintenance

Having delved into the world of Machine Learning for quality control, we’ve witnessed how AI fine-tunes automotive production. But what if we could go a step further? What if we could predict when a machine might falter and fix it before it flinches? Welcome to reducing downtime with predictive maintenance in the AI-driven Automotive Industry.

Imagine a factory where machines speak a language only AI comprehends. They send signals, subtle hints of distress, deciphered by algorithms. To ensure maximum efficiency, we can proactively replace any component showing signs of fatigue without delay or hesitation. There are no more unexpected halts, just seamless production.

This predictive prowess not only saves time but also slashes expenses. Traditional maintenance schedules often mean replacing parts prematurely. With AI at the helm, we optimize costs, changing parts only when necessary.

But there’s more to the automotive world than efficient production. It’s also about getting the right parts at the right time. The next stop on our journey? Exploring how AI-driven supply chain optimization ensures that every piece arrives when needed. How does AI orchestrate this logistical masterpiece? Let’s explore.

Optimizing Supply Chains for Efficiency

Having explored how predictive maintenance keeps automotive plants humming, let’s shift our focus to another crucial facet of the AI-driven Automotive Industry: supply chains.

Imagine a world where the right parts seamlessly flow into assembly lines just in time. AI shapes this reality in the Automotive Industry. It’s about more than just predicting when machines might hiccup; it’s about orchestrating a symphony of components to meet production demands.

AI crunches mountains of data, considering factors like demand fluctuations, weather, traffic, and even geopolitical events. It optimizes routes, suggests inventory levels, and anticipates delays. The result? Leaner supply chains, cost savings, and delighted customers.

But it doesn’t stop there. AI isn’t just reactive; it’s proactive. It can predict surges in demand and ensure suppliers are ready, preventing costly bottlenecks. This level of foresight transforms supply chains into dynamic, responsive entities.

Imagine this finely tuned system working harmoniously with advanced robotics on the assembly line. How do these mechanical marvels enhance the modern car assembly process? Let’s delve into the role of robotics in modern car assembly and uncover the future of automotive manufacturing.

Role of Robotics in Modern Car Assembly

As we unravel the intricate web of innovations in the AI-driven Automotive Industry, we can’t ignore the pivotal role of robotics in modern car assembly. But how do these mechanical marvels fit into the broader picture of automotive manufacturing?

Picture a factory floor bustling with precision. Robots, guided by AI in the Automotive Industry, tirelessly assemble intricate parts with unmatched accuracy. They work hand in “gripper” with human counterparts, enhancing productivity while ensuring safety.

These robots aren’t just about speed; they’re about adaptability. They can swiftly switch tasks, accommodating various car models on the same line, reducing the need for extensive retooling. This agility is a game-changer in meeting customer demands.

Moreover, they never tire or lose focus. Consistency is their forte, ensuring each vehicle is built to perfection, bolstered by the vigilance of machine learning for quality control.

But what does this mean for the future of vehicle design? How does AI reshape the process of creating the cars of tomorrow? The next chapter will explore this fascinating journey: data-driven vehicle design. How will AI influence the aesthetics, safety, and sustainability of vehicles? Let’s find out.

Data-Driven Vehicle Design

Now that we’ve uncovered the transformative power of robotics in modern car assembly, it’s time to turn our attention to a pivotal aspect of automotive innovation: data-driven vehicle design. How does AI shape our vehicles’ aesthetics, safety, and sustainability?

In the realm of AI in the Automotive Industry, every curve, contour, and feature is meticulously crafted through the lens of data. Advanced algorithms analyze consumer preferences, safety standards, and even environmental impact to design vehicles that look stunning and function flawlessly.

Safety is paramount, and here, AI shines. It simulates countless crash scenarios, optimizing vehicle structures for maximum protection. Features like autonomous driving benefit from extensive data analysis, making our roads safer than ever.

But it’s not just about form and function. Sustainability takes centre stage. AI facilitates the use of eco-friendly materials and designs, contributing to sustainability through AI in the auto industry.

As we look ahead, it’s clear that AI will continue to mould future vehicles. How does this impact the broader landscape of green manufacturing in the automotive sector? Join us as we explore AI’s impact on green manufacturing, diving into the world of eco-conscious automotive production.

AI's Impact on Green Manufacturing

With data-driven vehicle design shaping the future of automobiles, the spotlight now shifts to a pressing concern: sustainability. How is AI revolutionizing green manufacturing in the AI-driven Automotive Industry?

AI doesn’t just design vehicles for the road; it designs them for a greener planet. By optimizing components and materials, AI contributes to more efficient fuel consumption and reduced emissions. Every journey becomes a step toward a sustainable future.

But the impact goes beyond the vehicles themselves. AI optimizes the entire manufacturing process, reducing waste and energy consumption. Factories equipped with intelligent sensors and algorithms fine-tune operations, minimizing environmental footprints.

Moreover, AI assists in recycling and reusing materials, closing the loop on automotive production. It envisions a world where the end of one vehicle’s life marks the beginning of another.

As we marvel at the strides made in green manufacturing, we must also ponder the future of the workforce. Join us on our journey to explore how we can train individuals with the necessary skills to harness the full potential of AI integrations in the automotive industry. Discover how we are preparing the workforce for the AI era and how it is shaping the future of mobility.

Skilling Workforce for AI Integrations

As we navigate the trailblazing path of AI’s impact on green manufacturing, one crucial aspect comes into sharp focus: preparing the workforce for the AI era within the AI-driven Automotive Industry.

AI’s potential is immense, but it requires skilled hands to unlock. The workforce must adapt, gaining proficiency in handling AI-integrated systems, from robotics to data analysis. But how do we equip individuals with these essential skills?

Imagine training programs that blend traditional automotive know-how with cutting-edge AI expertise. Workers become technologically versatile, capable of maintaining and optimizing AI-powered machinery. It’s a workforce transformation that promises increased productivity and efficiency.

AI professionals such as developers, data scientists, and machine learning engineers are becoming increasingly valuable in the industry, opening up new career paths.

As we delve into this transformative journey, let’s remember the power of real-world examples. What are the success stories in the automotive sector where AI integration and a skilled workforce have redefined the landscape? Join us as we explore these inspiring tales of innovation and progress.

Success Stories in the Automotive Sector

Amidst the transformative tide of AI and skilled workforce integration, the AI-driven Automotive Industry boasts remarkable success stories. These tales of innovation exemplify the incredible potential when technology and human expertise converge.

Consider the story of a leading automaker that leveraged AI for predictive maintenance. By predicting machine failures before they occurred, they slashed downtime by 40%, boosting production efficiency and customer satisfaction.

In another corner of the industry, a company embraced AI-driven supply chain optimization. The result? A streamlined operation with 30% less waste, quicker deliveries, and cost savings that rippled through the entire value chain.

Moreover, green manufacturing initiatives have flourished. A pioneering car manufacturer adopted sustainable AI-driven practices, reducing emissions by 25% while producing vehicles that excelled in safety and performance.

But these are just the opening chapters of what promises to be a thrilling automotive saga. What lies ahead as we continue to envision the Automotive Future? How will AI, skilled workforces, and sustainability shape the road ahead? Join us on this journey into uncharted territory.

Envisioning the Automotive Future

As the automotive industry celebrates its success stories, it is evident that significant transformation lies ahead. What does the future hold for the AI-driven Automotive Industry?

Picture this: self-driving cars seamlessly navigating urban jungles, powered by AI algorithms that predict traffic patterns, ensuring a smoother and safer commute. Sustainability takes centre stage, with vehicles running on alternative fuels optimized for efficiency through AI.

Robotics and AI have transformed the manufacturing industry, resulting in highly efficient production processes and expertly managed supply chains with minimal downtime. Furthermore, environmentally conscious manufacturing practices have become standard across the industry.

The workforce has evolved, too, with individuals skilled not only in traditional automotive craftsmanship but also in harnessing the power of AI. Collaboration between humans and machines becomes second nature, driving innovation to new heights.

However, challenges loom on the horizon. How do we address data privacy concerns in a world where vehicles are data hubs? Can AI adapt to the unpredictable nature of road conditions? Join us in the concluding part of this journey as we tackle these questions and peer into the horizon of the Automotive Industry’s future with AI. What new chapters will we write together?

Conclusion: Paving the Way for an AI-Driven Automotive Future

In this exhilarating journey through the transformative landscape of the automotive industry, we’ve witnessed the profound impact of AI in the Automotive Industry. From redefining quality checks with Machine Learning for quality control to foreseeing maintenance needs with predictive maintenance, every stride brings us closer to an era of unparalleled efficiency.

The optimization of supply chains ensures that the right components arrive just in time, a testament to the power of AI-driven supply chain optimization. Meanwhile, the symphony of robots and humans on the assembly line demonstrates the pivotal role of robotics in modern car assembly.

Data-driven design reshapes vehicles, making them safer, sleeker, and more sustainable. This is the legacy of sustainability through AI in the auto industry. But this is only possible with a skilled workforce adept at integrating AI, a testament to the importance of a skilled workforce for AI integrations.

As we’ve explored success stories, it’s clear that this isn’t just about innovation but revolution. The future, prosperous with self-driving cars, green manufacturing, and seamless human-AI collaboration, beckons. The question isn’t whether we’ll get there; it’s how. How do we navigate data privacy challenges and ensure AI adapts to unpredictability?

The horizon of the Automotive Industry’s future with AI is bright, and it’s a journey we embark on together. The chapters we write will redefine not only how we manufacture vehicles but also how we envision the future of mobility.

Related Articles

- AI in Paper Manufacturing: Pulp and Processors

- AI in Agri-Equipment Manufacturing: Fields and Functions

- AI in Footwear Manufacturing: Steps Ahead

- AI in Jewellery Manufacturing: Gems and Generative Models

- AI in Glass Manufacturing: Crystal Clear Computing

- AI in Construction Material Manufacturing: Bricks and Bytes

- AI in Chemical Manufacturing: Molecular Models

- AI’s Role in Electronic Manufacturing: Circuitry and Systems

- AI’s Revolution in Polymer Production: Reshaping Plastics

- AI in Furniture Manufacturing: Crafted by Code

- AI in Ceramic Production: Fired by Future

- AI in Food Manufacturing: Savory Systems

- AI in Metal Fabrication: Moulded by Machines

- AI in Aerospace Manufacturing: Beyond the Atmosphere

- AI’s Integration in Pharmaceutical Manufacturing: Pills and Processes

- Weaving AI into Textile Manufacturing: Threads and Tech

- IPA in Manufacturing Sector: How AI Tools Revolutionize Efficiency, Productivity, and Quality

Arindam Roy

An Automation Consultant with 25+ years of IT Experience

Forbes Articles related to AI usage in the Manufacturing Sector: