Revolutionizing Logistics

AI Tools for Precise Order and Shipment Tracking in the Industry's Fast Lane to Efficiency and Security

In the rapidly evolving logistics industry, cutting-edge technology integration has become imperative. “AI Tools for Order and Shipment Tracking in the Logistics Industry” stands out as a pivotal initiative, harnessing the power of artificial intelligence to revolutionize order and shipment tracking processes.

These tools, meticulously designed for efficiency and precision, encompass diverse functionalities such as automated proof of delivery, predictive delay notifications, intelligent package tracking, and shipment risk assessment.

This discussion delves into the intricate facets of developing and implementing these tools, addressing crucial aspects such as business knowledge requirements, software and hardware prerequisites, integration with existing toolsets, staff training needs, potential challenges, existing market solutions, and a comprehensive cost and benefit analysis.

Join us as we navigate the transformative realm of AI-driven logistics solutions, exploring the optimal strategies for their deployment in a dynamic and competitive industry.

Table of Contents

Arindam Roy

An Automation Consultant with 25+ years of IT Experience

5 AI Tool ideas for Order and Shipment Tracking

The AI Tools for Order and Shipment Tracking mentioned below can significantly enhance efficiency and decision-making in the Transportation and Logistics industry. Here’s an elaboration on each tool:

AI-Driven Shipment Visibility:

- Real-Time Tracking: Implement AI algorithms to provide accurate and real-time tracking of shipments. This could include GPS, RFID, and other sensor-based technologies to monitor the location of packages throughout the entire transportation process.

- Route Optimization: Utilize machine learning to analyze historical data and current traffic conditions to optimize real-time shipment routes. This can help reduce transit times and fuel costs.

Automated Proof of Delivery:

- Image Recognition: Use AI-powered image recognition systems to automatically verify proof of delivery by analyzing photos, signatures, or other relevant documentation captured at the delivery point.

- Blockchain Integration: Implement blockchain technology to create an immutable and transparent record of deliveries, ensuring the authenticity of proof of delivery.

Predictive Delay Notifications:

- Machine Learning Predictions: Analyze historical data and external factors (weather, traffic, holidays) using machine learning models to predict potential shipment delays. This enables proactive communication of expected delays to customers and stakeholders.

- Prescriptive Analytics: Suggest alternative routes or actions mitigate potential delays based on historical patterns and real-time data.

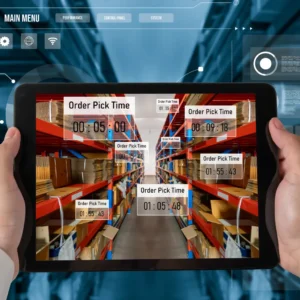

Smart Package Tracking:

- IoT Sensors: Integrate Internet of Things (IoT) sensors with packages to monitor environmental conditions (temperature, humidity) and detect any mishandling or damage during transit.

- Smart Tags: Use RFID or NFC tags to provide detailed information about the package and its contents, enabling more accurate and efficient sorting and tracking.

Shipment Risk Assessment:

- Predictive Analytics: Utilize predictive modelling to assess potential risks in the shipment process, such as route-specific risks, geopolitical factors, or customs-related challenges.

- Fraud Detection: Implement AI algorithms to detect anomalies in shipment data that could indicate fraudulent activities, helping prevent potential risks associated with illegal activities.

Collectively, these AI tools improve the efficiency, transparency, and reliability of transportation and logistics operations. They empower businesses to make data-driven decisions, enhance customer satisfaction through better visibility, and optimize resource utilization. Additionally, the Integration of AI can lead to cost savings, reduced delays, and improved risk management in the supply chain.

AI-Driven Shipment Visibility Tool

Business Knowledge Requirements:

- Logistics Operations Understanding: A comprehensive understanding of logistics operations, including order processing, warehousing, and transportation, to align the tool with industry-specific needs and challenges.

- Regulatory Compliance: Knowledge of regulations governing shipment tracking and route optimization to ensure the tool adheres to legal requirements.

- Customer Expectations: Insight into customer expectations regarding real-time tracking and delivery optimization for a better customer experience.

Software Requirements:

- Machine Learning Algorithms: Development of algorithms for real-time tracking and route optimization, utilizing machine learning techniques to improve accuracy and efficiency continuously.

- Geospatial Technologies: Integration with geospatial technologies such as GPS, RFID, and mapping services for precise location tracking and route analysis.

- Data Analytics Platform: A robust analytics platform is implemented to process and analyze historical and real-time data for route optimization.

Hardware Requirements:

- IoT Devices: Deploy devices like GPS trackers, RFID sensors, and other sensors on vehicles and packages to collect real-time data.

- Scalable Computing Resources: Availability of scalable computing resources to handle the processing demands of real-time tracking and route optimization algorithms.

Integration Requirements to the Existing Toolset:

- ERP and SCM Integration: Access relevant data for accurate tracking and optimization by seamlessly integrating with existing Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) systems.

- Communication Platforms Integration: Integration with communication tools to facilitate real-time updates and notifications to stakeholders, including customers and logistics managers.

- APIs for Data Exchange: Implementation of APIs for smooth data exchange with existing tools, ensuring interoperability and a cohesive logistics ecosystem.

Training Required for Existing Staff to Run the Tool:

- System Familiarization: Training staff to understand the functionalities and features of the AI-driven shipment visibility tool, enabling them to utilize data effectively.

- Data Security Training: Training on data security protocols to ensure protection and proper handling of sensitive shipment information.

Challenges and Workarounds in Implementing the Tool:

- Data Accuracy Challenges:

- Challenge: Ensuring real-time tracking data accuracy.

- Workaround: Implement data validation checks and leverage multiple data sources to enhance accuracy.

- Integration Complexity:

- Challenge: Integrating with diverse existing systems.

- Workaround: Employ middleware solutions or APIs that facilitate smoother integration.

Similar Tools already available in the Market:

- FourKites: Get real-time visibility into your supply chain with tracking, predictive analytics, and exception management features.

- Project44: Offers advanced visibility solutions, including real-time tracking and predictive analytics for logistics.

Cost and Benefit Analysis:

- Costs: Development costs, hardware investments, integration expenses, and ongoing maintenance.

- Benefits: Improved shipment visibility, reduced transit times, enhanced customer satisfaction, and potential cost savings through route optimization.

Recommendation: Integrate with Similar Available Products

Given the specialized nature of logistics and the availability of proven solutions, integrating with existing tools like FourKites or project44 is recommended.

Automated Proof of Delivery Tool

Business Knowledge Requirements:

- Logistics Operations Understanding: In-depth knowledge of logistics operations, including the delivery process, to design a tool that seamlessly integrates with existing workflows and addresses specific industry challenges.

- Legal and Compliance Knowledge: Understanding legal requirements and compliance standards related to proof of delivery to ensure the tool meets regulatory standards.

- Customer Expectations: Insight into customer expectations regarding verifying and transparent proof of delivery for a better customer experience.

Software Requirements:

- Image Recognition Algorithms: Development of AI-powered image recognition algorithms capable of automatically analyzing photos, signatures, and other relevant documentation to verify proof of delivery.

- Blockchain Integration Platform: Implementation of a blockchain integration platform to establish an immutable and transparent record of deliveries, ensuring data integrity and authenticity.

- Secure Database: Utilization of a secure database to store and securely manage proof of delivery data.

Hardware Requirements:

- High-Resolution Cameras: High-resolution cameras are deployed on delivery devices to capture clear images and signatures for accurate proof of delivery verification.

- Blockchain Nodes: If implementing a private blockchain, consider the hardware requirements for running and maintaining blockchain nodes for data validation and consensus.

Integration Requirements to the Existing Toolset:

- ERP and SCM Integration: Seamless integration with existing ERP (Enterprise Resource Planning) and SCM (Supply Chain Management) systems to synchronize proof of delivery data with other logistics processes.

- Blockchain Network Integration: Integration with existing blockchain networks or creating a new one, ensuring compatibility with the tool and other logistics systems.

- APIs for Data Exchange: Implementation of APIs to facilitate data exchange with other tools and platforms, promoting interoperability.

Training Required for Existing Staff to Run the Tool:

- Image Recognition Training: Training staff on using image recognition features for verifying proof of delivery, including interpreting results and handling exceptions.

- Blockchain Usage Training: Familiarize staff with blockchain technology, its role in the tool, and how to interact to ensure transparency and data integrity.

Challenges and Workarounds in Implementing the Tool:

- Data Security Challenges:

- Challenge: Ensuring the security of proof of delivery data, especially when integrating with blockchain.

- Workaround: Implement robust encryption protocols and access controls to safeguard sensitive information.

- Integration Complexity:

- Challenge: Integrating with diverse existing systems.

- Workaround: Utilize middleware solutions or APIs to streamline integration and ensure data flows seamlessly between systems.

Similar Tools already available in the Market:

- Zebra Technologies’ SmartPack: Utilizes image recognition and IoT technologies for proof of delivery verification.

- ShipChain: Incorporates blockchain to create transparent and secure supply chain records, including proof of delivery.

Cost and Benefit Analysis:

- Costs: Development costs, hardware investments, blockchain implementation costs, integration expenses, and ongoing maintenance.

- Benefits: Enhanced transparency, reduced disputes, improved data authenticity, and potential cost savings through automated processes.

Recommendation: Integrate with Similar Available Products

For this AI Tool, automated proof of delivery for Order and Shipment Tracking, integrating with existing solutions like Zebra Technologies’ SmartPack or ShipChain is recommended.

Predictive Delay Notifications Tool

Business Knowledge Requirements:

- Logistics Operations Understanding: In-depth knowledge of logistics processes, including transportation, routing, and delivery, to effectively analyze and predict potential shipment delays.

- External Factors Awareness: External factors such as weather, traffic, and holidays should be incorporated into predictive models to understand their impact on delays.

- Customer Expectations: Insight into customer expectations and industry standards for timely delivery to align the tool with customer satisfaction goals.

Software Requirements:

- Machine Learning Frameworks: Utilize machine learning frameworks and algorithms for predictive modelling based on historical data and external factors.

- Prescriptive Analytics Tools: Implement prescriptive analytics tools to suggest alternative routes or actions to mitigate potential delays and optimize the shipment process.

- Real-Time Data Integration: Incorporate real-time data feeds to enhance prediction accuracy and provide up-to-the-minute delay notifications.

Hardware Requirements:

- Scalable Computing Resources: Ensure access to scalable computing resources for processing and analyzing large datasets, especially when dealing with real-time data for predictive modelling.

- Cloud Infrastructure: Leverage cloud-based infrastructure for flexibility, scalability, and efficient data storage and processing.

Integration Requirements to the Existing Toolset:

- ERP and SCM Integration: Supply Chain Management (SCM) and Enterprise Resource Planning (ERP) system integration to access relevant historical and real-time data for predictive modelling.

- Communication Platforms Integration: Integrate with communication tools to enable automated notifications to customers, stakeholders, and internal teams.

- Data Exchange Standards: Adopt industry-standard data exchange protocols to ensure compatibility with existing logistics tools.

Training Required for Existing Staff to Run the Tool:

- Machine Learning Training: Provide training for staff to understand the machine learning models, their predictions, and how to interpret and act upon the information.

- Prescriptive Analytics Training: Familiarize staff with the prescriptive analytics features, enabling them to leverage alternative routes or actions the tool suggests.

Challenges and Workarounds in Implementing the Tool:

- Data Quality:

- Challenges: Ensuring historical data quality for accurate predictive modelling.

- Workaround: Implement data cleaning and validation processes to enhance data quality.

- Algorithm Interpretation:

- Challenges: Staff may need help to interpret machine learning predictions.

- Workaround: Provide user-friendly interfaces and comprehensive training to enhance understanding.

Similar Tools already available in the Market:

- ClearMetal (now with Project44): Utilizes machine learning to provide predictive intelligence for shipment visibility and proactive problem-solving.

- TransVoyant: Offers predictive analytics solutions for supply chain visibility and risk management.

Cost and Benefit Analysis:

- Costs: Development costs, software and hardware investments, integration expenses, training expenses, and ongoing maintenance.

- Benefits: Enhanced customer satisfaction, reduced disruptions in the supply chain, optimized routing for cost savings, and improved overall logistics efficiency.

Recommendation: Integrate with Similar Available Products

For this AI Tool, predictive delay notification for Order and Shipment Tracking, integrating with existing solutions like ClearMetal or TransVoyant is recommended.

Smart Package Tracking Tool

Business Knowledge Requirements:

- Logistics Operations Understanding: Deep knowledge of logistics operations, including packaging, sorting, and transportation, to align the tool with industry-specific needs.

- Environmental Regulations: Understanding regulations related to the transportation of goods, primarily those sensitive to environmental conditions, to ensure compliance.

- Inventory Management Knowledge: Insight into inventory management practices to optimize sorting and tracking processes.

Software Requirements:

- IoT Data Processing Platform: Implement a platform for processing data from IoT sensors, ensuring real-time monitoring of environmental conditions and timely detection of mishandling.

- RFID/NFC Data Integration: Develop software to integrate and process data from RFID or NFC tags, providing detailed package information for accurate sorting and tracking.

- Data Analytics and Reporting: Utilize data analytics tools for analyzing collected data, generating insights, and creating comprehensive reports for logistics managers.

Hardware Requirements:

- IoT Sensors: Deploy IoT sensors capable of monitoring environmental conditions such as temperature and humidity.

- RFID/NFC Tags: Utilize RFID or NFC tags for packages to provide detailed information and enable efficient sorting and tracking.

- Data Storage Solutions: Implement secure and scalable data storage solutions to manage the vast data that IoT sensors and RFID/NFC tags generate.

Integration Requirements to the Existing Toolset:

- ERP and SCM Integration: Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) system integration to enhance overall supply chain visibility.

- Inventory Management Integration: Optimize sorting and tracking with inventory management systems using RFID/NFC tags.

- Communication Platforms Integration: Integration with communication tools to facilitate real-time alerts and notifications based on IoT sensor data.

Training Required for Existing Staff to Run the Tool:

- IoT Sensor Monitoring Training: Train staff on monitoring and interpreting data from IoT sensors, ensuring timely responses to environmental changes.

- RFID/NFC Tag Handling Training: Familiarize staff with handling packages with RFID or NFC tags and interpreting the information for sorting and tracking.

Challenges and Workarounds in Implementing the Tool:

- Data Security:

- Challenges: Ensuring data security is collected from IoT sensors and RFID/NFC tags.

- Workaround: Implement robust encryption protocols and access controls to safeguard sensitive information.

- Integration Complexity:

- Challenge: Integrating with diverse existing systems.

- Workaround: Utilize middleware solutions or APIs to streamline integration and ensure data flows seamlessly between systems.

Similar Tools already available in the Market:

- Parcelive by Tive: IoT sensors offer real-time visibility into the condition and location of shipments.

- Savi Visibility: Provides end-to-end visibility solutions for supply chain tracking, including IoT-based environmental monitoring.

Cost and Benefit Analysis:

- Costs: Development costs, hardware investments, integration expenses, training expenses, and ongoing maintenance.

- Benefits: Improved package tracking accuracy, reduced mishandling incidents, enhanced environmental condition monitoring, and potential cost savings through optimized processes.

Recommendation: Integrate with Similar Available Products

For this AI Tool, smart packaging tracking for Order and Shipment Tracking, integrating with existing solutions like Parcelive by Tive or Savi Visibility is recommended.

Shipment Risk Assessment Tool

Business Knowledge Requirements:

- Logistics Operations Understanding: In-depth knowledge of logistics operations, including transportation, customs procedures, and geopolitical considerations, to accurately identify and assess potential risks.

- Compliance and Regulatory Knowledge: Understanding international trade regulations, customs requirements, and shipping compliance to incorporate these factors into risk assessments.

- Fraud Pattern Awareness: Knowledge of common fraud patterns and activities in the logistics industry to enhance the accuracy of fraud detection algorithms.

Software Requirements:

- Predictive Analytics Software: Implement predictive analytics tools for modelling potential risks in shipment processes based on historical data and external factors.

- Fraud Detection Algorithms: Develop and integrate AI algorithms capable of detecting anomalies in shipment data flagging potential fraudulent activities.

- Data Visualization Tools: Logistics managers can make informed decisions by utilizing data visualization tools to present risk assessments in a clear and actionable manner.

Hardware Requirements:

- Scalable Computing Resources: Ensure access to scalable computing resources for processing large datasets and running complex predictive analytics models.

- Secure Data Storage: Implement secure and scalable data storage solutions to store and manage the extensive data used for risk assessments.

Integration Requirements to the Existing Toolset:

- ERP and SCM Integration: Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) system integration to access relevant data for risk assessment.

- Customs Software Integration: Integration with customs-related software to obtain real-time data on customs procedures and regulations.

- Communication Platforms Integration: Integration with communication tools for real-time alerts and notifications based on risk assessments.

Training Required for Existing Staff to Run the Tool:

- Predictive Analytics Training: Train staff on understanding and interpreting results from predictive analytics models for effective decision-making.

- Fraud Detection Training: Familiarize staff with the fraud detection algorithms and educate them on recognizing and responding to potential fraudulent activities.

Challenges and Workarounds in Implementing the Tool:

- Data Quality Challenges:

- Challenge: Ensuring the quality and accuracy of data used for predictive modelling and fraud detection.

- Workaround: Implement data cleaning processes and regularly update databases with accurate information.

- Algorithm Fine-Tuning:

- Challenge: Fine-tuning predictive analytics and fraud detection algorithms for optimal accuracy.

- Workaround: Conduct regular assessments and adjustments based on feedback and changing risk factors.

Similar Tools already available in the Market:

- CargoSignal: Offers predictive risk analytics and monitoring for global shipments.

- Savi Insight: Provides supply chain visibility and risk management solutions, including predictive analytics.

Cost and Benefit Analysis:

- Costs: Development costs, software and hardware investments, integration expenses, training expenses, and ongoing maintenance.

- Benefits: Enhanced risk mitigation, reduced losses due to fraud or delays, improved compliance with regulations, and increased overall supply chain security.

Recommendation: Integrate with Similar Available Products

For this AI Tool, shipment assessment tracking for Order and Shipment Tracking, integrating with existing solutions like CargoSignal or Savi Insight, is recommended.

Conclusion on AI tools for Order and Shipment Tracking

In conclusion, developing AI tools for order and shipment tracking in logistics involves a strategic blend of business knowledge, cutting-edge software, and robust hardware infrastructure. The chosen tools—Automated Proof of Delivery, Predictive Delay Notifications, Smart Package Tracking, and Shipment Risk Assessment—embrace technologies like image recognition, blockchain integration, machine learning, and IoT sensors to enhance visibility, efficiency, and security in the supply chain.

Considering the organization’s status as an IT/AI pioneer in the transportation and logistics industry, the recommendation is to integrate with similar available products rather than build from scratch or buy off the shelf. Integration offers a faster time-to-market, leverages industry expertise embedded in established solutions, proves cost-efficient, and ensures scalability to meet evolving business needs.

By integrating with proven tools such as those offered by ClearMetal, TransVoyant, Parcelive by Tive, Savi Insight, and others, the organization can capitalize on existing innovations, mitigate implementation risks, and deliver immediate value to its logistics operations. This approach aligns with the organization’s commitment to advancing technologically in the transportation and logistics sector, ultimately fostering a more resilient, secure, and efficient supply chain.

Related Articles

- AI Tools for Predictive Analytics and Business Intelligence

- AI Tools for Sustainability and Green Logistics

- AI Tools for Compliance and Regulatory Support

- AI Tools for Fleet Maintenance and Monitoring

- AI Tools for Operational Efficiency and Automation

- AI Tools for Supply Chain Visibility and Collaboration

- AI Tools for Warehouse Management and Automation

- AI Tools for Route Optimization and Planning

- AI Tools for Risk Management and Security

- AI tools in the Transportation and Logistics industry